Matrosovskoe deposit

LLC Gepar has a license to subsurface usage MAG # 13978 BE to produce gold and associated components in Matrosovskoye man-made field in Magadan region, which was issued by Regional Agency for subsurface usage in Magadan region. The license is valid till March 1, 2027.

LLC Gepar has a license to subsurface usage MAG # 13978 BE to produce gold and associated components in Matrosovskoye man-made field in Magadan region, which was issued by Regional Agency for subsurface usage in Magadan region. The license is valid till March 1, 2027.

The license area was given a status of mining lease. Area of the lease comprises 0.21 km2.

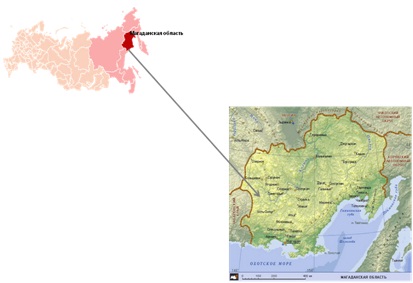

The License area is located in Tenkinsky district of Magadan region in the river Omchak valley (left inflow of the river Tenka). Economically the region is well developed, and characterized with availability of roads, power supply, developed infrastructure, and availability of local labor resources.

The field is connected to the regional center Ust-Omchug settlement (128 km) with an earth road of class III with all-year-round traffic of vehicles. Distance from Magadan sea port comprises 390 km, to Sokol airport - 335 km, of which 298 km – on earth road of class III and the remaining distance – on a road with concrete or bitumen paving. Electrical power is supplied to Omchak settlement in a centralized way from Kolyma hydro power station. The region has sufficient labor resources as the main activity of the population id gold production.

The License area includes man-made dumps formed in the period of 1944-1986 as a result of piling wastes of ore mining and remains of gold ore processing at mineral processing factory of the mine named after Matrosov. By technical description it is an artificial water body of hill and dam type. By geomorphologic description it is a valley train formed by depositions of man-made origin.

Height of the dam above surrounding valley comprises 21-23 m. Length of tailing pit is 1140 m, maximal width is 430 m, total area is 37 Ha. Key designation of the dam is provision of slope stability and containment of tails in the tailing pit. In the process of the pit filling the dam was periodically extended upwards. Tails were supplied from the factory in the form of pulp. After settling during warm season of the year contained in the pulp water was discharged through a sough into the river Omchak. During winter period tails were frozen in the tailing pit. Under such conditions the facility was functioning from 1944 till 1986, when it was closed due to opening of new tailing pit in the valley of Glukhar brook. During that period 16.3 mln. tons of tails with average gold content 1.0 g/t was discharged into the pit.

By specifics of geological structure MMF is referred to Group III of effective classification.

Geological and mining description of the field determines an open separate method of development.

An option is considered to either use dozer development with water jet washing out of sands, or use a system of hydraulic development of the field sands with washing out from the lower horizon. The field reserves in the order of their development are divided into 4 approximately equal pits with constructed dams between them.

MMF is considered ready for commercial development.

In 1994 LLC VNII-1 performed process testing of MMF ores, and on the basis of its results the company TOO Technologies of open and subsurface mining (Magadan) developed Feasibility study for conditions of man-made gold ore field «Tails of Matrosov mineral processing factory». Performed surveys confirmed a possibility of efficient dressing of old tails at Matrosov mineral processing factory using traditional methods without significant change of technology of operating factory at the level of commercial gold recovery 64.1-66.6%. The main drawback of this scheme is its orientation to operation of the old Matrosov mineral processing factory, which is currently completely dismantled. In addition, process solutions made in this feasibility study are significantly outdated and need to be reviewed using experience in application of new gravitation and flotation methods of ore dressing.

In this relation an issue was raised on new investigation of ore process properties, and in May 2008 LLC Gepar took an ore sample and sent it for analysis in the amount of 470 kg to LLC NIiPI TOMS (Irkutsk). As a result of studying material composition of ores, surveys of ore dressing using gravitation methods, hydrometallurgical surveys, studies of material composition of ore dressing products, determination of tail dehydration and compressibility parameters, conducting tests on neutralization of cyanidation tails a staged gravitation method of ore dressing was suggested with production of various concentrates and their further processing by means of intensive and sorption cyanidation. The proposed scheme of ore dressing includes stages of physical and chemical demercuryzation. The final product is gold-silver alloy DORE.